What You Need to Know

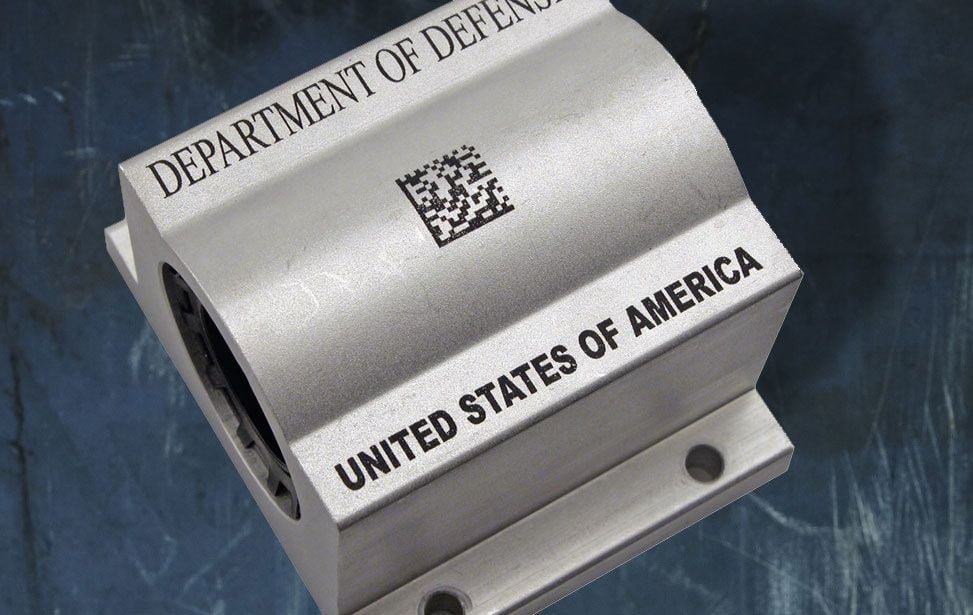

Barcodes are everywhere. Those are the black-and-white labels you notice in shops, on packaging, and many other services and products. Barcodes make it simpler to listen to music and discover objects. Laser marking machine manufacturer are one of the satisfactory equipment for the barcode era. It produces fast, accurate, and precise barcodes that close a long term.

What is a laser marking tool?

A marking device wherein a laser uses a laser beam to mark the ground.These symbols may be letters, numbers, photos, in this case, or barcodes.

| View more |

The laser beam is very effective and can mark almost any object. Common substances encompass steel, plastic, glass, and even paper.

The laser works by removing a small quantity of material from the surface or changing the material’s color. This produces a clean signal that may be examined or scanned. Laser marking is a clean and precise procedure, making it perfect for barcodes.

How Does Laser Marking Work for Bar Codes?

Here is a simple way to apprehend how laser marking for barcodes works.

Barcode practice: Barcode statistics (numbers, letters, or statistics) are entered into the device, which converts it into black and white dots and area.

Focus the laser: The laser is centered at the region wherein the barcode could be marked, including metallic or plastic.

Mark the page: The laser follows the definition of the barcode, heats the web page to modify cloth or put off small parts, growing dark and mild regions of the barcode.

Benefits of Using Laser Marking for Bar Codes

Laser marking has many benefits when it comes to barcode layout. Here are a number of the most crucial ones:

1. Clear and accurate signage

Laser marking machines are very accurate. This is crucial for barcodes because even minor errors could make the code unreadable. The laser marking tool ensures that the barcode is manageable and sharp enough to be traced easily.

2. Permanent bar code

Bar codes with laser markers are everlasting. This way, they didn’t put on out, put on out, or damage down over the years. The barcode stays legible whether the product has been heavily changed or the cloth has been revealed. This is right for industries requiring lengthy-term tracking, whether in-car or scientific.

3. No contact with the web page

Laser marking is a non-touch process. This manner that the laser does now not physically contact the object floor. This reduces waste. It additionally has less wear and tear on the device, resulting in a more extended existence.

4. No ink or lettering is required

Traditional marking techniques commonly use ink or stickers. However, none of this is vital for laser marking. It is a smooth method that leaves no mess. You don’t have to worry about inking or completing, and no traces can peel off. It additionally means less upkeep.

5. Fast and green

Laser marking is a fast procedure. It can see many stuff in a short period. Whether you need to mark hundreds or hundreds of items a day, a laser marker can deal with it.

6. He works on many stuff

Laser marking is flexible. It works on many materials, including metallic, plastic, glass, and even wood. This makes it an excellent preference for varied agencies.

Industries That Use Laser Marking for Bar Codes

Many businesses use laser marking to create barcodes. Here are some of the essential industries that benefit from this era:

1. Automotive Industry

In the automobile industry, components of motors should be inspected from manufacturing to meeting. The barcode helps with this, and laser marking guarantees that the barcode is durable and will now not be damaged through warmness or chemicals.

2. Electronics

Many minor additives are used in the electronics enterprise. These elements ought to be accompanied cautiously. Laser marking lets, in particular, bar codes be created on small digital surfaces without damage.

3. Medical Services

Tracking could be very critical for gadgets and equipment in the medical area. Laser-marked barcodes on surgical and clinical contraptions assist in ensuring safety and prevent errors.

4. The area venture

The aerospace industry additionally relies on barcodes for song parts and systems. Laser marking offers durable bar codes that could face intense conditions consisting of excessive temperatures and lengthy intervals of use.

5. Food and beverage service

Bar codes track meals and beverage products from manufacturing to sale. Laser marking on packaging guarantees that barcodes are clean and will now not be broken at some stage in transportation or storage.

How to pick a laser marker for barcodes

If you’re thinking about using a laser marking gadget to create barcodes, here are a few matters to hold in mind while deciding on the proper system.

Laser power: Choose an excessive-electricity laser to mark complex surfaces together with metal. For smooth substances, which include plastics, low-energy lasers are generally suitable.

Accessories: Make sure the gadget works nicely with the accessories you’ll use. Some lasers are satisfactory for metals, while others are appropriate for plastics or materials.

Ease of use: Choose devices with straightforward controls and consumer-pleasant software. This allows the acceleration of the method and decreases errors.

Cost and renovation: Laser markers are funded, but ink and labels don’t store cash. Find a tool for your budget that doesn’t require principal renovation.

Conclusion

The laser marking system is an exceptional option for barcodes. They are accurate and rapid and may mark a wide variety of items. Whether you’re within the automobile, electronics, medical, or food industries, laser marking offers a smooth and green way to create permanent barcodes.

With the proper laser marking device, you can ensure that your barcodes are clean, readable, and durable. This makes it easier to tune and identify items, improving productiveness and lowering mistakes in your paintings.

Leave a Reply