When it comes to creating an accurate piece of machinery, precision machining plays the most crucial role in doing it. Almost every industry using tools or machines relies on precision machining to design and create different kinds of tools.

One of the most prominent uses of precision machining is noticeable in the beauty industry. There are plenty of tools and machines used in the beauty industry that require the touch of precision machining to achieve perfection and function properly for the users.

Here we dive deep into how precision machining is taking the beauty industry ahead in the game with its impact on the tools and machines. Let’s get started.

What is Precision Machining?

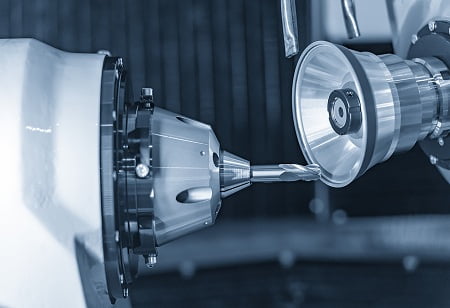

Precision machining is the process of producing parts for tools, machines, and other manufacturing components. It’s a computer-controlled machinery system that uses a high-velocity machining process to create parts that require tight tolerances and high complexity.

The process can involve a highly skilled operator or a high-speed robot depending on the company and its capability of expenditure. It’s a very straightforward process where the machine will start removing material from a block or a piece to give it the shape of the required part.

Parts created with precision machining are accurate in measurement and smooth in the finishing touches. Most of the time these parts are interconnected with other parts and components which is why it’s crucial to maintain the accuracy. Precision machining typically relies on two factors that make it an effective way to create machine components. These are –

- The machine has to have a high-end cutting tool that is capable of removing material from a block or a stock piece following the perfect measurements and dimensions.

- It has to have a CNC or computer numerical control machine to complete the process so that the cutting tool is controlled with precision following the direction of the CNC machine.

Applications of Precision Machining in the Beauty Industry

Now that you know a bit about precision machining, let’s talk about how precision machining is impacting the beauty industry. Several different tools use the wonders of precision machining to achieve functionality and perfection in them. Some popular tools that use precision machining and its technologies are as follows.

- Hair Removal Device

Hair removal devices often use precision machining technologies to craft the intricate parts. The main body of the device is usually crafted from ABS plastic which incorporates the injection molding procedure to create the main body of the device.

Then, to create the intricate and internal components of the device CNC machining is used. Parts like the head which contains the tweezer or blades of the machine are created from custom CNC machining services which combines computer programs to precisely control the cutting tool to create complex and accurate shapes.

To finish it off, all the parts go through a layer of electroplating and painting to make them corrosion-resistant while making them look aesthetically pleasing.

- Hair Dryer

Aluminum is a popular choice for hair dryers because of its excellent heat conductivity and lightweight nature. Precision machining ensures the housing is precisely shaped to house the internal components and optimize airflow.

This involves techniques like CNC milling, which uses a rotating tool to remove material from the aluminum block, and drilling to create holes for air vents and controls. The machining process eliminates any rough edges left behind from cutting or imperfections, resulting in a smooth and sleek finish.

To further enhance the look and feel of the hair dryer, manufacturers might opt for additional finishing processes like polishing, which creates a shiny surface, or anodizing, which creates a protective and decorative oxide layer.

- Hair Curler

Similar to hair dryers, aluminum or even high-temperature-resistant plastics could be used for the curler’s body. Precision machining ensures the barrel, where hair is wrapped for curling, and the clamps that hold the hair in place are precisely shaped. This is crucial for even heat distribution during operation and a secure hold on different hair types.

When it comes to the surface finish, a smooth, heat-resistant coating is very important. This might involve processes like Teflon coating, which provides a slick surface that minimizes hair snagging and allows for smooth gliding.

- Face Massager

The material selection for a face massager depends on factors like the desired weight for user comfort, heat conductivity, and hypoallergenic properties to avoid skin irritation. Stainless steel or medical-grade plastics are the most common choices for face massagers.

Precision machining comes into play for creating the massaging elements themselves, such as rollers or vibrating pads. The machining ensures these elements have the precise shape and dimensions needed to deliver the desired massaging effect. Additionally, machining allows for the creation of ergonomic handles or grips for comfortable use.

The final touch often involves a polished or plated finish. This not only enhances the aesthetics of the massager but also promotes hygiene by creating a smooth and easily cleanable surface.

Common Machining Process in the Beauty Industry

Precision machining isn’t just the method of cutting or removing material. There are plenty of processes behind the precision machining technology. Here we talk about the particular processes that are used in manufacturing tools in the beauty industry. Let’s get started.

5 Axis CNC machining:

This advanced technique takes CNC machining to the next level. A standard CNC machine typically has 3 axes (X, Y, and Z) that control the movement of the cutting tool. 5-axis CNC machining adds two more rotational axes (often A and B), allowing the tool to approach the workpiece from virtually any angle.

There are several advantages of using 5-axis CNC machining for creating beauty tools. Such as –

- High Precision

The ability to maneuver the cutting tool from multiple angles ensures exceptional accuracy and eliminates the need for multiple setups on simpler CNC machines.

- Complexities Made Easy

This process tackles intricate designs with ease, allowing for innovative features and shapes that enhance functionality and aesthetics.

- Reduced Waste

5-axis machining minimizes material waste by allowing parts to be machined from a single block of material, unlike traditional methods that might require multiple pieces to be assembled later.

Sheet Metal Fabrication:

This process involves transforming sheets of metal into desired shapes through various techniques. It’s a cost-effective solution for creating specific components of beauty tools, particularly for parts that don’t require extreme precision or complex geometries.

Sheet metal fabrication offers several benefits in creating various beauty products. These include –

- Cost-Effective

For simpler shapes, sheet metal is a budget-friendly option compared to processes like CNC machining.

- Lightweight and Durable

Metals like aluminum provide a good balance of weight and strength, ideal for many beauty tool components.

- Fast Production

Sheet metal fabrication can be a relatively quick process, especially for high-volume production runs.

Injection molding:

This process doesn’t involve machining in the traditional sense, but it’s a crucial part of beauty tool production. Injection molding utilizes molds to create identical plastic parts. Molten plastic is injected into a precisely carved mold cavity, then cooled and solidified to take the shape of the mold.

Injection molding is used in a lot of beauty tool devices, especially for creating the body of the device. Here are some benefits that the beauty industry gets from the injection molding process –

- High Repeatability

The process ensures consistent and identical parts, ideal for mass production. It makes sure all the beauty tools follow the same design pattern and are consistent in functionality.

- Design Flexibility

A wide variety of plastic materials and mold designs offer great flexibility in terms of functionality, aesthetics, and weight.

- Cost-Effective for High Volume:

For large production runs, injection molding becomes a very cost-effective way to create plastic components.

Advantages of Precision Machining in the Beauty Industry

Precision machining offers quite a lot of benefits for the beauty industry, contributing to the creation of visually appealing, high-performing tools that elevate the brand image and enhance the consumer experience. Here’s a quick rundown on the advantages of using precision machining in the beauty industry –

- Appearance and durability:

Precision machining allows for the creation of parts with tight tolerances and smooth finishes. This translates to beauty tools with clean lines, sharp edges, and a more professional look compared to those made with cruder methods.

The controlled nature of machining minimizes material waste and allows for the use of higher-quality materials like stainless steel or aluminum. These materials offer inherent durability, resisting corrosion, and wear better than less precisely machined parts.

Also, tight tolerances ensure parts fit together seamlessly and move smoothly, reducing friction and wear. This translates to beauty tools that function flawlessly for a longer period.

- Product performance:

The creation of intricate features and mechanisms that optimize performance is another crucial benefit you get from precision machining. For example, precisely machined channels in a hair dryer ensure efficient airflow for faster drying.

Precise control of the machining process guarantees consistent part dimensions and eliminates inconsistencies that could affect performance. This translates to reliable and predictable results from beauty tools.

It also opens doors for innovative features and designs like allowing for the creation of complex heating elements within hair curlers or intricate massage rollers in facial massagers.

- Brand premium:

The use of high-quality materials and meticulous craftsmanship creates a perception of premium quality and professionalism. This elevates the brand image in the eyes of consumers, allowing beauty companies to command a higher price point.

It also helps in creating unique and visually striking designs that set a brand apart from the competition. This fosters brand recognition and loyalty.

- Consumer experience:

Precision machining ensures parts fit together seamlessly and function smoothly. This translates to beauty tools that are comfortable to hold, easy to operate, and deliver a more enjoyable user experience.

The use of durable materials and precise assembly reduces the risk of malfunctions or breakdowns. This instills confidence in consumers when using beauty tools.

Visually appealing tools with a premium feel enhance the overall user experience. Consumers appreciate the attention to detail and quality reflected in precision-machined beauty tools.

Design Tips for New Product Release

Releasing a new product in any industry can be a pretty daunting challenge for a business. If you are completely new in the industry or planning to get into one, then check out these design tips that can help you with the new product release in your business.

- Certifications: FDA certified

Certifications ensure your product meets specific safety and quality standards set by regulatory bodies of a state or a country. It works to prove that your product maintains the standards, and consumers won’t have to worry about the safety or the quality of the product. FDA certification is particularly important for beauty products that make medical claims or come into direct contact with the body.

- Control Over Budget

Just because you are releasing a new product, doesn’t mean you should go all out with it. You have to have a clear budget breakdown for design, materials, manufacturing, marketing, and distribution. It will help you stay on track financially and avoid unnecessary expenses. It also allows you to make informed decisions about resource allocation and potential cost-saving measures

- Soft power: such as intellectual property and other certifications

Soft power basically means intangible assets that give your product a competitive edge. Things like patents or trademarks help protect your unique design or technology, preventing competitors from copying it. Other certifications, such as those related to sustainability or ethical sourcing, can also enhance your brand image and attract environmentally or socially conscious consumers.

- Potential legal risks in various countries

Before launching your product globally, it’s essential to understand the legal landscape in different countries. Regulations regarding ingredients, labeling, safety testing, and intellectual property can vary significantly. Consulting with legal experts specializing in international trade can help you navigate these complexities and avoid potential legal roadblocks.

- Stable Manufacturer Supplier

Having a reliable and trustworthy manufacturer is vital for consistent product quality and on-time delivery. Factors to consider include the manufacturer’s experience with similar products, quality control procedures, production capacity, and track record of meeting deadlines. Building a strong relationship with your manufacturer ensures smooth communication and collaboration throughout the production process.

Start a Beauty Business Today with Zintilon

Are you planning on starting a beauty business today? In that case, Zintilon might be the perfect partner to help you out in the journey.

At Zintilon, you can turn all your manufacturing ideas into reality. Whether it’s CNC machining for hair dryers Sheet metal fabrication for hair clipper blades, or even die casting for housing elements, they have got you covered with everything.

With 20-plus years of experience in manufacturing machine parts and components, Zintilon will never let you down with the quality and functionality of the machines.

So, if you are thinking of launching a beauty brand, then Zintilon can be the perfect manufacturing partner in your journey.

Conclusion:

To conclude, precision machining is a crucial aspect of the beauty industry these days. As beauty tools require perfection in functionality, and aesthetics at the same time, it’s important to employ different precision machining techniques to achieve that perfection. And a company like Zintilon can certainly help you achieve that in your business.

Leave a Reply