Butterfly valves are popular in many industries. They are compact, efficient, and provide reliable flow control. These valves are vital in pipelines. They enable precise, easy control of fluid flow. Yet, it is crucial to know if a butterfly valve is open or closed. This ensures efficiency, prevents leaks, and maintains safety. This guide will explore butterfly valves in detail. It will cover their design, function, position indicators, and maintenance tips.

For top butterfly valves, visit the Butterfly Valve Manufacturer. They have the best solutions for your industry needs.

Understanding the Basic Structure of Butterfly Valves

Components of a Butterfly Valve

A butterfly valve consists of the following essential parts:

- Valve Body: Connects the valve to the piping system.

- Disc (Butterfly Plate): Rotates to open or close the valve.

- Valve Stem: Links the disc to the actuator or handle.

- The seat ensures a tight seal when the valve closes.

- Actuator or Handle: Controls the movement of the valve disc.

This design’s simplicity leads to its use in many industries. They include water treatment, HVAC, and petrochemical.

Working Principle of a Butterfly Valve:

Butterfly valves operate on a quarter-turn mechanism. Rotating the valve handle or actuator by 90 degrees opens or closes the valve. When open, the disc aligns parallel to the flow, allowing fluid to pass. In the closed position, the disc is perpendicular, blocking the flow completely.

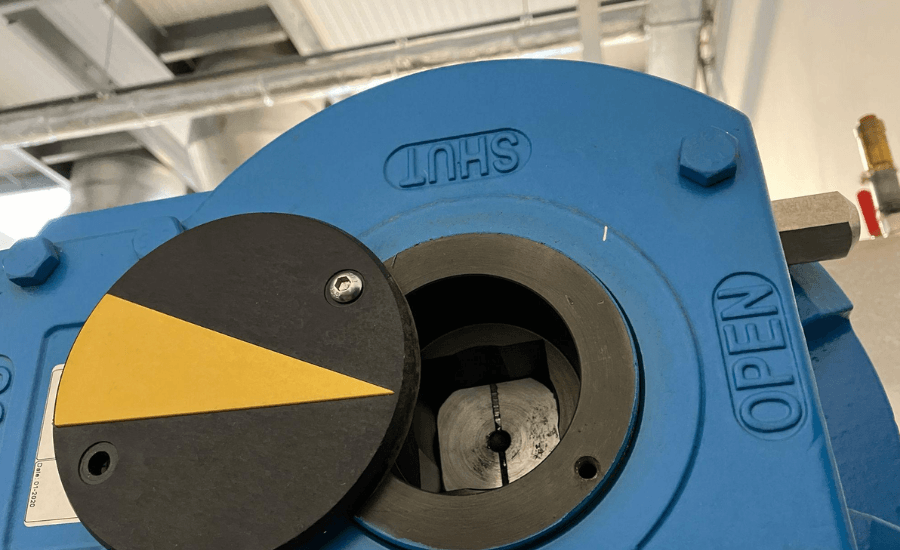

Identifying the Position of a Butterfly Valve:

Visual Indicators:

- Handle Position:

- If the handle aligns with the pipeline, the valve remains open.

- If the handle is perpendicular to the pipeline, it closes the valve.

- Stem Orientation:

- In manual valves, the stem’s alignment often follows the same principle as the handle.

- Position Indicators on Actuators:

- Automatic butterfly valves with electric or pneumatic actuators often have position indicators, like arrows or LEDs. They show whether the valve is open or closed.

Testing Flow:

If the above indicators are unclear, you can perform a controlled flow test:

- Open a nearby outlet and observe whether fluid passes through when you assume that the valve is open.

- If no fluid flows, the system may have a closed or malfunctioning valve.

Advantages of Knowing the Valve Position:

Operational Efficiency: Prevents energy loss due to improper valve settings.

System Safety: Minimizes the risks of leaks, overpressure, or backflow.

Maintenance Planning: Helps diagnose valve or pipeline issues.

Common challenges in determining valve positions:

Obstructed Indicators: Dirt, corrosion, or poor lighting may obscure visual indicators.

Misaligned Handles or Stems: Wear can cause misalignment, leading to false readings.

Faulty Actuators: Automated systems may misreport their position due to faulty actuators.

Regular inspection and maintenance can address these challenges with great success.

Tips for Maintaining Butterfly Valves

Regular cleaning prevents the buildup of debris or corrosion on the valve components.

Lubrication: Ensures the smooth operation of the stem and actuator.

Inspect the seal: Check the seat for wear and replace it if you observe leakage.

Periodic Testing: Check the valve’s open and closed positions. This ensures that the indicators work.

For expert advice and premium-quality valves, consult the Butterfly Valve Manufacturer.

Applications Where Valve Position Matters:

1. Water and Wastewater Management:

- Ensures efficient flow regulation and prevents contamination.

2. HVAC Systems:

- Maintains optimal heating and cooling by controlling fluid flow in the system.

3. Petrochemical Industry:

- Prevents hazardous leaks by ensuring that valves remain tightly closed during maintenance.

4. Food and Beverage Industry:

- Guarantees hygiene by controlling the flow of liquids and cleaning agents.

Features to Look for in a Butterfly Valve:

Clear Position Indicators: Simplify determining whether the valve is open or closed.

Durable Materials: Enhance longevity and resistance to wear.

Reliable seals prevent leakage and ensure operational safety.

Customization Options: Tailored solutions for specific industry needs.

For customized and durable butterfly valves, contact the Butterfly Valve Manufacturer today.

Conclusion

To check a butterfly valve’s position, use visual indicators and tests. They are simple, but their effective use is essential. Regular maintenance and high-quality valves can simplify this task. They will ensure your system operates with optimal performance and security.

For reliable butterfly valves or expert help, contact the Butterfly Valve Manufacturer. They provide top-notch solutions. They offer a wide range of valves, from manual to automated designs. We tailor them to meet the unique demands of various industries.

Read Next: Networkustad.co.uk

Leave a Reply